For over a decade, Kelvin Giormani has been supplying the world with the most contemporary sofa designs and is known in the market as always delivering on quality and design. Kelvin Giormani sofas are renowned for bringing together the latest in sofa design, and quality European components. All lounges are finished with a feeling of luxury, in 100% Italian leather. The designers at Giormani consider every detail of their designs so you can expect a product made with style and innovation in mind. In order to ensure the quality of leather used, Kelvin Giormani always remain quality supply from Mastrotto Italia (of Gruppo mastrotto spa) and Peretti Gruppo. Full grain and Aniline leather preserves the natural hand touch and characteristics of natural cow hides. Using this category of leather in sofas gets you closer to nature every day.

Website: Kelvin Giormani

High Level Customization

Over 70 Genuine Leather Colors to Choose From

There are 5 main categories (including 10 different leather articles and altogether 53 colors) of either Italian-made or German-made genuine leather within the KELVIN GIORMANI leather collection.

In addition, with the partnership of the largest Italian international leather tannery group, Gruppo Mastrotto spa, we have join developed a high-performance starting leather grade being made in either South America or Asia with the choice of 18 colors.

We welcome the combination of different leather colors within a sofa set. From the design stand point, we recommend no more than 3 leather colors within a sofa set.

Size Alteration

Sizes of a sofa, such as, seat width, seat depth, seat height, back height can be altered, within certain limitations, to fit your personalized preference.

Alteration surcharges will apply, and please ask our team for details.

Since sofa is a kind of soft upholstery product, please kindly allow the size tolerance within +/- 3cm.

Choice of Different Sofa Legs

For selected sofa models only, there are possibilities of changing different style of legs based on the limited options that are provided.

Choice of Different Wooden Leg Colors

In KELVIN GIORMANI, we have 6 standard colors of wooden legs, namely, Wenge Color (no. 219), Beech Color (no. 019), Cherry Wood Color (no. C02), Dark Walnut Color (no. W01), Solid Black Color (no. R05) and Silver Gray Color (no. 210).

Choice of Stitching Types & Colors

There are 6 different stitching types available for customization, namely, Single Stitching (regular), Single Stitching (thick), Single Stitching (fine), Double Stitching, Leather Piping Cord and Leather Edging Stitch. Please kindly note that not very sofa model is suitable for all 6 types of stitching, please ask our team for details.

Besides stitching types, you can choose to contract colors on 4 stitching types, namely, Single Stitching (regular), Single Stitching (fine), Double Stitching and Leather Piping Cord.

Seat Softness Adjustment

In KELVIN GIORMANI, we rate our sofa seat softness from Level 1 to Level 7. The higher it is the Level, the softer it is the sofa seat.

Please note that there is no absolute standard for each Seat Softness Level. In other words, due to the design and structure variance on different sofa models, you might feel slight difference of seat softness for different models even when they have the same Seat Softness Level. The purpose of this rating level system is mainly to let us have a better reference of how you prefer to harden or soften your sofa’s seat comfort from the standard of a particular sofa model.

Also, we don’t recommend this adjustment goes up or down more than 2 levels because that will significantly affect other aspects of seating, such as, feeling of seat height, seat and back pitch, lumber support, etc.

Personalizing Leather-crafting Features

In KELVIN GIORMANI, we believe that beautiful leather-crafting features, such as, weaving, perforation, special pattern stitching and folding effect, etc., should not only be found in fashion goods like hand bags, shoes or clothings. Personalize your KELVIN GIORMANI sofa sets with a fashionable leather-crafting feature in your preferred leather surface areas.

Adding Seat-sliding or Head Mechanisms

For selected sofa models only, there are possibilities of adding seat-sliding or head mechanisms to enhance the comfort of the models. Both mechanisms are constructed with key parts that are made in Germany by reputable companies.

Leather Stories

Quality Assurance by Name Brand European Tanneries

Why do quality oriented sofa makers always work with European name brand tanneries?

After genuine cow hides have been processed, even professionals sometimes can’t accurately classify the quality standard with bare hands. Also, not all European tanneries are certified by international quality assessment institutions. In order to ensure the quality of leather used, KELVIN GIORMANI always remains quality supply from Mastrotto Italia (of Gruppo Mastrotto spa), Peretti Gruppo and HELLER-LEDER GmbH & Co. KG.

Aniline & Full Grain Leather

Full Grain and aniline Leather preserves the natural hand touch and characteristics of natural cow hides. Using this category of leather in sofas gets you closer to nature everyday.

High Performance Pigmented Leather

Thanks to Italian & German advanced leather tanning technology, water and stain resistant characteristics can be added onto high performance pigmented leather without damaging the natural characteristics and softness. Having this category of leather in sofas, users can easily use neutral detergents to clean up many different kinds of stains on sofas.

Stories of Genuine Leather

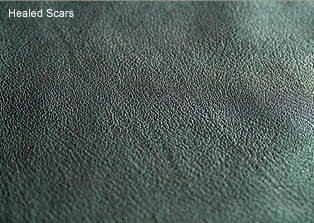

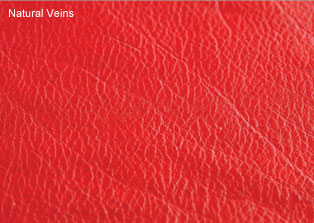

Leather is a natural material. To give sofa users the natural touch of leather , KELVIN GIORMANI always reminds our Italian tanneries to minimize any unnecessary surface correction and chemical process onto a piece of cow hide. As a result, Kelvin Giormani preserve also the natural characteristics which can only be found on genuine leather, such as, healed scars, natural veins and neck marks, natural variance on colors and grains. Kelvin Giormani loves to feel the naturalness of genuine leather sofas, and they also appreciate everything that comes together with natural leather

Kelvin Giormani Leather Categories

ORVIETO

Made by the Italian international tannery group, the Gruppo Mastrotto spa, in Asia or South America.

Tannery: Gruppo Mastrotto spa

Top grain leather with strong fibers resistant to tears comparing with splits or fabrics. It breathes naturally and regulates temperature when it absorbs and releases humidity through natural pores which cannot be found in splits or artificial leather.

Appearance: Matt

Thickness: 1.3-1.5mm

Corrected meaning that the leather has been sanded (or buffed) to reduce the visibility of natural markings of raw hides.

Pigmented (dyed) with protected color-finishing on leather surfaces that serves to waterproof and ensures color consistency as well as high durability. It will just slightly fade under long sunlight exposure and is very well protected against normal household stains.

Embossed with Dollaro Americano Print creates uniform appearance and greater texture on the leather surface. Embossing is a process that re-creates the leather surface pattern and makes it smoother as well as softer by dry milling. Our embossing process preserves the natural elegance and the feel of premium leather.

Most popularly-used leather category for high-end contemporary sofas.

EURO SOFT

Made in Italy with primarily South American raw hides.

Tannery: Gruppo Peretti Italy

Top grain leather with strong fibers resistant to tears comparing with splits or fabrics. It breathes naturally and regulates temperature when it absorbs and releases humidity through natural pores which cannot be found in splits or artificial leather.

Appearance: Matt

Thickness: 1.2-1.4mm

Semi-corrected meaning that the leather has just been slighted buffed to try to keep its natural characteristics. This type of process is sometimes referred to as “half grain,” or “mezzo fiore.” This means that there has been some buffing (correction) on the hides, hence the follicle is not as evident as before but the mechanical friction of the buffing process is not as strong as to strip most of the characteristics and strength of the natural leather.

Slightly pigmented (dyed) with protected color-finishing on the leather surface that serves to waterproof and ensures color consistency as well as high durability. The pigmentation of this leather is done with a very thin, yet, reliable and resistant layer of high quality pigment to try to preserve as much as possible the naturalness of the leather. It will just slightly fade under long sunlight exposure and is well protected against normal household stains.

No embossing has been applied and the grain seen on the leather surface comes naturally and with variation within a hide. Without embossing, by just applying a simple milling process, the natural softness of the leather can be better preserved.

It’s perfect for users who want as much as possible the luxury flair and the natural touch of leather but try to minimize the effort of maintaining genuine leather.

SPESSO

Made in Italy with primarily South American raw hides.

Tannery: JBS Italy

Top grain leather with strong fibers resistant to tears comparing with splits or fabrics. It breathes naturally and regulates temperature when it absorbs and releases humidity through natural pores which cannot be found in splits or artificial leather.

Appearance: Matt

Thickness: 1.6-1.8mm

Corrected meaning that the leather has been sanded (or buffed) to reduce the visibility of natural markings of raw hides.

Pigmented (dyed) with protected color-finishing on leather surfaces that serves to waterproof and ensures color consistency as well as high durability. It will just slightly fade under long sunlight exposure and is very well protected against normal household stains.

Embossed large-grain prints create uniform appearance and greater texture on the leather surface. Embossing is a process that re-creates the leather surface pattern and makes it smoother as well as softer by dry milling. Our embossing process preserves the natural elegance and the feel of premium leather.

SPESSO can be applicable to almost all KELVIN GIORMANI models.

KING

Made in Italy with primarily South American raw hides.

Tannery: Gruppo Mastrotto Italia

Top grain leather with strong fibers resistant to tears comparing with splits or fabrics. It breathes naturally and regulates temperature when it absorbs and releases humidity through natural pores which cannot be found in splits or artificial leather.

Appearance: Semi glossy

Thickness: 1.3-1.5mm

Semi-corrected meaning that the leather has just been slighted buffed to try to keep its natural characteristics. This type of process is sometimes referred to as “half grain,” or “mezzo fiore.” This means that there has been some buffing (correction) on the hides, hence the follicle is not as evident as before but the mechanical friction of the buffing process is not as strong as to strip most of the characteristics and strength of the natural leather.

Slightly pigmented (dyed) with protected color-finishing on the leather surface that serves to waterproof and ensures color consistency as well as high durability. The pigmentation of this leather is done with a very thin, yet, reliable and resistant layer of high quality pigment to try to preserve as much as possible the naturalness of the leather. It will just slightly fade under long sunlight exposure and is well protected against normal household stains.

No embossing has been applied and the grain seen on the leather surface comes naturally and with variation within a hide. Without embossing, by just applying a simple milling process, the natural softness of the leather can be better preserved.

It’s perfect for users who want as much as possible the luxury flair and the natural touch of leather but try to minimize the effort of maintaining genuine leather.

MARCO PRO

Made in Italy with primarily European raw hides.

Tannery: Gruppo Peretti Italy

Top grain leather with strong fibers resistant to tears comparing with splits or fabrics. It breathes naturally and regulates temperature when it absorbs and releases humidity through natural pores which cannot be found in splits or artificial leather.

Appearance: Semi glossy with silky hand.

Thickness: 1.3-1.5mm.

Semi-corrected meaning that the leather has just been slighted buffed to try to keep its natural characteristics. This type of process is sometimes referred to as “half grain,” or “mezzo fiore.” This means that there has been some buffing (correction) on the hides, hence the follicle is not as evident as before but the mechanical friction of the buffing process is not as strong as to strip most of the characteristics and strength of the natural leather.

Semi-aniline based leather which is colored with a transparent dye containing aniline (as a result, color variation within a hide can happen). Aniline is a colorless liquid that helps to open pores of the leather. Aniline leather has very limited amount of chemicals being applied which makes it the softest and finest upholstery leather.

No embossing has been applied and the grain seen on the leather surface comes naturally and with variation within a hide. Without embossing, by just applying a simple milling process, the natural softness of the leather can be better preserved.

This type of leather is at the top of the leather collection as a sofa being made with this leather literally lives with the owner and increases its softness with usage and time.

Mechanisms

HETTICH

Quality Mechanisms from Name Brand International Manufacturers

HETTICH has been for years as a well-known German company which supplies a large variety of furniture hardwares and mechanisms. KELVIN GIORMANI is pleased to include some of them in their sofas that give functionality and durability.

Kemmann & Koch

Kemmann & Koch

Quality Mechanisms from Name Brand International Manufacturers

Kemmann & Koch is one of the few German companies which has over 80 years of history of producing mechanisms for sofas. Inheriting the German manufacturing tradition of reliability and durability, Kemmann & Koch has always been an important source of mechanisms which construct the core of many KELVIN GIORMANI sofas.

LUSCH

LUSCH

Quality mechanisms from Name Brand International Manufacturers

LUSCH is a highly regarded German manufacturer of sofa mechanisms. KELVIN GIORMANI always develops stylish European-design sofa functions and special features with LUSCH mechanisms.

STABILUS

Quality mechanisms from Name Brand International Manufacturers

STABILUS is the world’s largest manufacturer of gas lifts & related products with production facilities over 10 countries around the world. To ensure the Italian mechanisms being used in Kelvin Giormani sofas perform smooth and reliable motions, KELVIN GIORMANI particularly chooses the German-made STABILUS gas lists to be the core of many of their sofas with motions.

LEGGETT & PLATT

LEGGETT & PLATT

Quality mechanisms from Name Brand International Manufacturers

LEGGETT & PLATT is the world’s largest manufacturer of sofa mechanisms and a FORTUNE 500 American company. KELVIN GIORMANI uses its “Zero-wall” recliner mechanisms for years.

SEDAC MERAL

Quality mechanisms from Name Brand International Manufacturers

SEDAC MERAL is a Belgium based company who is the largest sofa bed mechanism manufacturer in Europe with production in various countries. Kelvin Giormani has been using their sofa bed mechanisms since 1999, and they are one of their first European partners on supplying sofa mechanisms.

International Synergy

International Synergy

Quality mechanisms from Name Brand International Manufacturers

Some says KELVIN GIORMANI sofa is melting pot of elements from different parts of the world. Kelvin Giormani are proud to make good use of highly skilled handwork from the country of their origin, being incorporated with European modern designs and German production techniques as well as the materials and mechanisms from American and European companies.

Hardwares

Engineering of sofa Feet 1

Understanding the important of the both the structure and east-to-assemble, KELVIN GIORMANI makes the sofa feet, if necessary to be detached when packing ready to be assembled and disassembled with a simple tool and bare hands without big effort.

Engineering of sofa Feet 2

Short sofa feet are always already assembled to save customer’s effort at the marketplace. Small plastic knobs under all types of sofa feet are to avoid any corner or edge of sofa feet from damaging users’ flooring materials.

Smart Connectors 1

Special plastic buckles to fix the loose back cushions.

Smart Connectors 2

Specialized metal hardware for connecting sofa modules with loose seat cushions.

Smart Connectors 3

Metal hardware to connect modules of a sofa composition.

Smart Connectors 4

Special metal buckles to fix loose seat cushions.

Smart Connectors 5

Having zippers to connect a back cushion top onto a sofa frame top, KELVIN GIORMANI sofa back cushions can easily be maintained at the proper shape and position.

Wooden Frames

Sofa Frames of German Engineering Standard

KELVIN GIORMANI only uses selective hardwood materials to build a frame. Softwood like pine was never a choice.

KELVIN GIORMANI always treats inside elements of a sofa no less important than the outside. The quality of a person is originated from inside, and so are KELVIN GIORMANI sofas.

Having long years of producing sofas with the label of a name brand German sofa maker, KELVIN GIORMANI also build frame of Kelvin Giormani’s in-house name with the same standard.

Strong glues on all wood joints and using of corner blocks are important elements.

All wooden materials are kiln-dried to ensure low moisture level and prevent the frame from twisting.

KELVIN GIORMANI always treats inside elements of a sofa no less important than the outside. The quality of a person is originated from inside, and so are KELVIN GIORMANI sofas.

Padding Materials

High Quality inside Stuffing Materials

The density and quality of the foams used are supplied and assured by large scale, specialized factories. The products are tested as if they are used for a considerable amount of time.

KELVIN GIORMANI sofa cushions and edges foams are always wrapped by extra sheets of high density polyester fibers. Additional work and time devoted for this procedure gives KELVIN GIORMANI sofas a more luxury appearance and comfortable seating.

The density and quality of the foams used are supplied and assured by large scale, specialized factories. The products are tested as if they are used for a considerable amount of time.

Precision of foam cutting is important to the expression of the design elements of KELVIN GIORMANI sofas.

Properly gluing leather covers on foams is a little thing that greatly enhances the durability of KELVIN GIORMANI sofas.

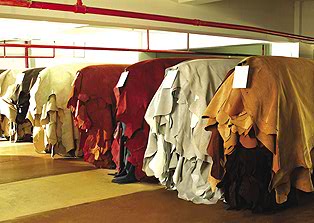

Craftmanship

KELVIN GIORMANI always keeping millions of sq. ft. of leather in stock enhances on time delivery of finished sofas.

Cutting leather with care ensures the best results on sewing leather covers.

KELVIN GIORMANI proudly continues the tradition of “drafting” and “cutting” the leather as two separate procedures to better allocating natural characteristics to proper portions of a sofa.

Quality sewing beautifully outlines the design and ensures the durability of every sofa.

High performance sewing machines are keys to achieve every pretty and durable stitching line.

Quality

Every single piece of leather is checked and graded manually before putting onto the production line.

Controlling for the correct measurement and quality of wooden parts is important to guarantee the long-lasting structure of each KELVIN GIORMANI sofa frame

Without the proper technical requirement of the sinuous spring, KELVIN GIORMANI sofas will never achieve the right seating comfort and durability.

A usual gesture of KELVIN GIORMANI sewing technicians to check the smoothness of every stitching line.

“Size does matter.” This is one of the concepts of each quality control staff of KELVIN GIORMANI’s.

A usual gesture of KELVIN GIORMANI sewing technicians to check the smoothness of every stitching line.

Besides our in-house label, KELVIN GIORMANI, we also develop different quality control standards with different brands of sofas produced in our factory according to their requirements.